Engineering

Our engineering group comprises one of the deepest offerings among tool builders worldwide. Specific areas of expertise include:

- Die cast tool design & design for manufacturability and OEE.

- Flow, thermal and stress analysis.

- Gating, overflow and runner design.

- Die casting process development & troubleshooting.

- Die cast tooling and casting materials and alloys.

- Die surface treatment & coating.

- Infrared thermography.

- Hydraulic and electrical systems.

Engineering

- Exco's strength in engineering spills over into our commitment to after sales, on-site support. Particularly on large new programs, Exco’s staff will ‘live’ at our customer’s facility - at no charge - until a stable and efficient production environment is achieved.

- We do not have a sales department - close contact between our engineering group and our customers provides the foundation for a strong understanding of customer needs and an efficient working relationship.

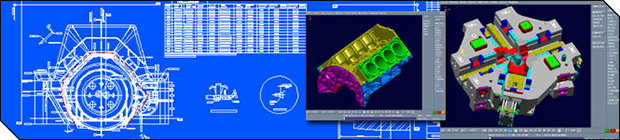

- Grouped into customer and account-dedicated teams, Exco can import, translate, and design in all leading contemporary CAD packages.

- CAE & Upfront Engineering: We can provide upfront engineering service to optimize casting design to achieve the best cast-ability and the lowest manufacturing cost.

- We employ concurrent engineering in CAE to achieve the optimal die casting die design at every phase of the project and gain the biggest operational window for the die casting process, with state-of-the-art CAE tools such as Flow-3D, MagmaSoft, Ansys and Exco-Vent.